Technology & solutions

A load of latest plastics and rubber applications in automobiles

Automotive plastics and rubber play a crucial role in the innovations for all types of automobiles and in a wide spectrum of applications, including the interior, exterior, under-bonnet, and others. Technological advancement in the materials further boosts the development of the automotive industry beyond the conventional realm.

Owing to their advantages of lightweight, ease of processing, design flexibility, and possible sourcing from sustainable raw materials, high-end plastics and rubber are increasingly used to replace metals in automotive components, without compromising on performance and safety.

The latest examples of automotive plastics and rubber applications reveal how the rapid development of the materials is driving the mobility forward.

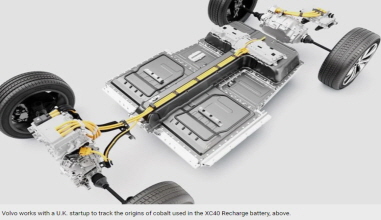

PA6 enclosure for high-voltage EV battery

Technical plastics such as polyamide 6 (PA6) offer numerous benefits for the design of battery enclosures for electric vehicles (EVs), such as sustainability, manufacturing costs, weight savings and economical functional integration.

To prove such plastic enclosures can meet the very demanding mechanical and flame-retardant requirements, Kautex Textron and LANXESS carried out a comprehensive examination using a jointly developed technology demonstrator made from PA6.

The results showed that the near-series demonstrator passes all relevant mechanical and thermal tests. An enclosure prototype has been being road tested in a test vehicle to verify its suitability for daily use. The companies are currently jointly tackling the first series-production development projects with automotive manufacturers.

The large-format all-plastic enclosure, which measures around 1,400 millimeters in both length and width, meets the requirements of the mechanical shock test and crush test. The results of the drop and vibration tests were also positive, as were those of the bottom impact test.

The demonstrator also proved its resistance to external sources of fire underneath the vehicle in accordance with ECE R100 (external fire).

Besides, calculations revealed that the carbon footprint of the plastic enclosure is over 40% smaller compared to an aluminum design.

The lower energy use in the production of PA6 compared with metal as well as other factors, such as the omission of time-consuming cathodic dip painting to prevent corrosion where steel is used, help to minimize the carbon footprint.

The thermoplastic component design also makes recycling the enclosure easier compared with thermoset materials such as sheet molding compounds (SMC).

As explained, the demonstrator was developed based on the aluminum battery housing of a mid-size EV and designed for mass production. It is manufactured in a single-stage compression molding process with a molding compound based on the PA 6 compound Durethan B24CMH2.0 from LANXESS and does not require any further rework.

Crash-relevant areas are specially reinforced with locally placed blanks made from the continuous-fiber-reinforced, PA6-based composite Tepex dynalite 102-RGUD600. Compared with an aluminum design, there is a weight saving of around 10%, which is advantageous for the range and therefore the carbon footprint of the vehicle.

The integration of functions, such as the fasteners, reinforcing ribs and components for the thermal management, reduces the number of individual components significantly. This simplifies assembly and logistical effort and reduces manufacturing costs.

Blow molding monolayer hybrid vehicle fuel tank

As e-mobility continues to leap forward, regulations and standards are evolving alongside the automotive industry. European union regulations set a maximum CO2 emission rate of 95g/km for passenger cars, which necessitates a balance of materials and design to maximize fuel efficiency.

DSM Engineering Materials has announced its partnership with Renault to develop an industry-first lightweight solution for hybrid vehicle fuel tanks.

By using Akulon Fuel Lock, DSM's high-performance low-carbon-footprint PA6 material, the fuel tanks can be produced with a blow molding monolayer construction that significantly reduces weight and cost without compromising safety or risking additional emissions.

Plug-in hybrid vehicles enable the use of smaller fuel tanks, making a polymer solution more viable, but high-density polyethylene (HDPE) still requires multilayer structures with complex additional features to prevent permeation and withstand the extended periods of internal pressure inherent to Plug-in hybrid vehicles.

Akulon Fuel Lock PA6 grades are designed for injection or blow molding and extrusion, making them highly versatile for the design innovation of the e-mobility sector. High parison stability enables very narrow wall thickness distribution, and robust performance at both high and low temperatures ensures paramount safety.

The materials thereby offer a drop-in solution and a second life to the monolayer blow molding machines dedicated to the production of the declining diesel monolayer fuel tanks.

Engineering plastic used in front fender

LG Chem has started supplying LUCON TX5007 engineering plastic to Mitsubishi Motors for its powder coating parts used as the front fenders of the RVR, Delica D:5 and Outlander models.

Front fender is located on the side of the vehicle, which not only acts as one of key factors in the exterior design but also protects wheels from road debris. Therefore, it not only should possess high mechanical robustness but also high exterior quality.

LUCON TX5007 is a compound material that combines modified polyphenylene ether (mPPE) and polyamide (PA66) alloy with carbon nanotubes (CNTs). It has high electrical conductivity and shows strong mechanical properties.

Moreover, the material has high heat resistance, making it suitable for the automotive on-the-line painting process at 200°C or higher. At the same time, it provides high dimensional stability thanks to its low coefficient of linear thermal expansion (CLTE).

When a plastic fender is used, the weight of the vehicle is reduced by about 4kg, which also improves fuel efficiency. It can also provide other benefits, such as reduced fuel exhaust emission and carbon footprint.

Using CNT in engineering plastics can support diverse requirements. CNT is a filler that provides high conductivity even with a small amount. The material covers a wider range of electrical conductivity compared to other carbon fillers such as carbon black and carbon fiber.

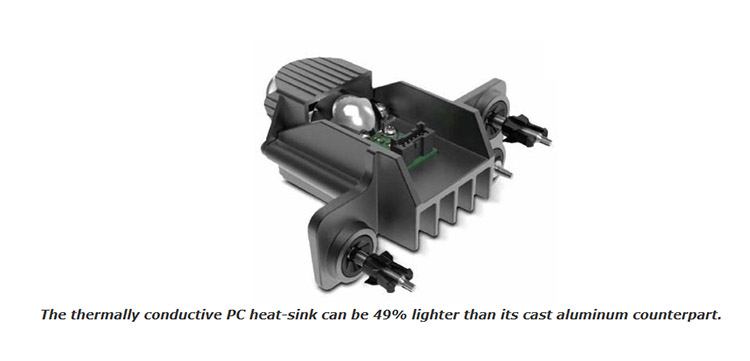

Lightweight PC heat-sink for car lighting

X2F has teamed up with Covestro to develop a thermally conductive automotive heat-sink with in-mold electronics (IME) using X2F’s transformative controlled viscosity molding technology.

This new product molded of Covestro's Makrolon polycarbonate (PC) is approximately half as heavy as the typical aluminum part.

It is part of an in-mold assembly that can be used to integrate LED modules directly into the headlamp housing, eliminating the weight and labor associated with the installation of brackets, screws, thermal pastes, and adhesives.

According to Covestro, the LED module is attached directly onto the thermally conductive heat-sink without fundamentally changing the heat-sink adjuster module design.

The X2F technology is production-ready and has been demonstrated in high-volume series manufacturing for other applications. It enables sensitive electronics to be insert molded, thus providing functional integration, heat management, modularity, and miniaturization.

This innovative technology enables the manufacture of previously impossible-to-mold thermoplastic parts. The result is 30-200% improvement in performance depending on the applications and materials used, says X2F.

In the case of heat-sink, it dramatically streamlines production, reduces manufacturing times, eliminates fasteners and paste, and increases product design flexibility.

X2F’s ability to mold thermally conductive materials has applications far beyond heat-sink. Thermal management is critical for superior performance in battery, motor, and printed circuit board applications.

X2F has recently added a rotary table that reduces cycle time and facilitates higher-volume production for its controlled viscosity molding machine. Production volume can reach up to four million parts per year with one unit depending on the cycle time.

Bio-attributed PVC for seat upholstery

Independent Volvo spin-off and high-performance EV manufacturer Polestar has adopted INEOS Inovyn's BIOVYN in the seat upholstery for its new Polestar 3 SUV model.

BIOVYN bio-attributed vinyl is made of 100% renewable feedstock that does not compete with the food chain. It replaces fossil based raw materials with renewable materials obtained from crude tall oil, a byproduct of coniferous tree pulping.

Having the same properties as conventional polyvinyl chloride (PVC), BIOVYN is billed as the first bio-attributed PVC available for commercial use that enables a carbon footprint reduction of over 70%. It is also the first PVC product certified by the Roundtable on Sustainable Biomaterials.

First released in 2019, BIOVYN was designed to meet performance and quality requirement in different industry sectors while moving society closer to a circular and carbon neutral economy.

Meanwhile, another INEOS Group company INEOS Styrolution’s Luran S SPF 30 grade has been selected for rear spoiler application in Dolphin model by BYD Auto.

Luran S is the acrylonitrile styrene acrylate (ASA) copolymer brand of the company, boasting high weathering, impact and chemical resistance.

The company’s portfolio of ASA products can be formulated with enhanced UV stability, such as SPF 30, to further increase protection from UV exposure. Luran S also offers high design flexibility due to its colorability and dimensional stability.

In addition, the material provides good surface adhesion, making it possible for car manufacturers to overlay the Luran S substrate with a hot-stamped foil for decorative features on exterior parts.

Translucent polyolefin foam for automotive interior

How people interact with vehicles and how interiors can be optimized are catching more attention in future mobility. Seeing a growing trend towards making surface multifunctional, Sekisui Alveo has developed translucent foam for use in automotive interior.

The special foam allows light to pass through soft trim elements such as the dashboard and door panels, displaying information or providing illumination. It drives the trend in automotive interior design, particularly that of EVs.

The breakthrough in this new technology is translucent foam. Foams are typically opaque due to their cell structure and various components. However, they can be made translucent.

The newly developed foams include the PE foams TL LV and TLA LV, in white and natural. They are suitable for applications with low thermal requirements like door roll and door panel.

Thermal requirements are higher for applications above the belt line where polypropylene (PP) foams are required. The European manufacturer of high-quality polyolefin foams is now developing PP foams with greatly improved translucent properties.

Bio-based PU system for automotive acoustic applications

ACOUSTIFLEX VEF BIO system is the bio-based viscoelastic foam technology launched by Huntsman for molded acoustic applications in the automotive industry. It contains up to 20% bio-based content derived from vegetable oils.

This new solution can lower the carbon footprint of automotive carpet back-foaming by up to 25% compared to existing Huntsman systems for this application. The technology can also be used for dash and wheel arch insulation.

There was a concern that incorporating bio-based content into a polyurethane (PU) foam system would have a detrimental impact on performance, specifically on emission and odor levels. The development of ACOUSTIFLEX VEF BIO system proves that doesn’t need to be the case, emphasizes Huntsman.

When it comes to acoustic performance, analysis experiments show that original VEF systems can outclass standard high resilient (HR) foams at lower frequencies (<500 Hz). ACOUSTIFLEX VEF BIO system achieves the same magnitude of sound reducing capability.

In developing ACOUSTIFLEX VEF BIO system, the company has continued its work in the development of zero-amine, zero-plasticizer, and extremely low aldehyde emitting PU foams. As a result, the system is both low emission and low odor, and remains lightweight as VEF systems.

The company's automotive team has also ensured there are no associated processing disadvantages, with high productivity rates and demold times as low as 80s depending on part design.

Synthetic rubber solutions to boost NEV development

In line with the increasing demands for sustainable mobility, ARLANXEO develops advanced synthetic rubber products and solutions with local innovation capabilities and collaboration across the industry chain.

Leveraging the company’s environmentally-friendly Keltan ACE catalyst technology, Keltan Ultra-high Mooney 100+ Innovation Platform is primarily focused on the development of new and sustainable synthetic rubber grades with high Mooney viscosity, to optimize physical properties and cost, for upgraded applications in the automotive, transportation, and other sectors.

The platform carries four grades currently. The new grade of Keltan 10675C has better abrasive resistance and elasticity, catering to the needs for customized new energy vehicles (NEVs) parts, such as wiring harness systems.

Meanwhile, Keltan 10660C possesses both ultra-high molecular weight and a combination of processing and mechanical properties. It is applied to automobile hoses and railway rubber parts. Keltan 10950C features excellent extrusion performance, offering an alternative for producing high-performance sponge seals for automobiles and buildings.

For tire technology, ARLANXEO teamed up with Bridgestone and Solvay to launch TECHSYN, which combines chemically optimized synthetic rubber with tailor-made silica to achieve up to 30% better wear efficiency and up to 6% less rolling resistance. The result is an overall reduction of fuel consumption and CO2 emissions.

In addition, the Changzhou Li-ion Battery Lab located in ARLANXEO’s headquarter in China is designed to contribute to developing energy storage solutions for NEVs with customers.The lab was upgraded with a new pouch cell line, thus enables it to fully support research and development of Li-ion battery, including optimizing battery materials to improve battery energy density, exploring solutions in accordance with customer’s production process, enhancing production processes to reduce production costs, etc.

Demonstration tire made from 90% of sustainable materials

Goodyear has unveiled a demonstration tire comprised of 90% sustainable materials, which has passed all applicable regulatory testing as well as the company’s internal testing.

The demonstration tire was also tested to have lower rolling resistance when compared to the reference tire made with traditional materials. Lower rolling resistance represents the potential to offer better fuel savings and carbon footprint reduction.

As introduced, 17 featured ingredients across 12 different components are included in the demonstration tire. Four different types of carbon black, which are produced from methane, carbon dioxide, plant-based oil, and end-of-life tire pyrolysis oil feedstocks, are used.

The use of soybean oil helps keep the tire’s rubber compound pliable in changing temperatures. High-quality silica produced from rice husk waste residue (RHA silica) is used to help improve grip and reduce fuel consumption.

Traditional petroleum-based resins for enhancing tire traction performance are replaced with bio-renewable pine tree resins. The technical grade polyester for tire cords comes from post-consumer bottles recycling. ISCC certified mass balance polymers from bio- and bio-circular feedstocks are also included.

Goodyear explained that bringing a 90% sustainable-material tire to market will require further collaboration with its supply base to identify the scale necessary for producing the materials to produce that specific tire at high volumes.

Nevertheless, the tire manufacturing company plans to sell a tire with up to 70% sustainable material content in 2023 and introduce a 100% sustainable-material tire by 2030.

source : https://www.adsalecprj.com/web/news/article_details?id=61510&lang=1

edit : handler